With the deployment of Oracle NetSuite Manufacturing, one can manage all product data through an integrated platform. Manufacturing units can take better control of all the processes through robust capabilities of this cloud ERP for Manufacturing.

NetSuite for Manufacturing

- Control, coordinate, and manage all manufacturing aspects

- Manage complex manufacturing operations with ease

- Power and agility to adapt to trending market opportunities

- Manage procurement and plan production at a single instance

- Multi-language and multi-currency support for global supply chain

- One-stop solution for all production processes with real-time visibility

Drive Greater Efficiency and Gain Profitability with NetSuite, an ERP engineered for Manufacturing

Product Data Management

Oracle NetSuite ERP for Manufacturing helps maintain all the key operations to run manufacturing including

- Items

- Customers

- Partners

- Vendors

Planning and Scheduling

NetSuite Advanced Manufacturing Module automatically balances demand and supply to help businesses ensure the right inventory in the right place at the right time.

NetSuite for Manufacturing Companies has come up with a solution to reduce the complexities and achieve the desired results without compromising usability.

NetSuite ERP for manufacturing Industry achieves this balance with extensive features including

- Real-Time Scheduling Engine

- Flexible Scheduling Code

- Finite And Infinite Capacity Scheduling

- Multiple Graphical Representations

- Drag And Drop Scheduled Operations

Production Control

By leveraging the elemental functionalities of NetSuite for Manufacturing, companies engaged across this sector can create, release, update, and monitor work orders throughout the production process with the least hassle.

NetSuite offers extensive production control capabilities to backflush, track WIP, and capture labor.

- Automatic status updates with workflow

- Real-time view

- Batch updates

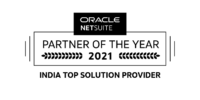

NetSuite Staircase

Our Clients

Shop Floor Control

This Manufacturing ERP & Management Software delivers real-time updates to help business leaders make well-informed decisions. Also, this ERP Software for Manufacturers helps them drive user satisfaction, data accuracy to enhance manufacturing operations.

Quality Management

With this Manufacturing ERP Software, manufacturing units can define inspection plans, pass or fail criteria, collect results, and monitor in real-time to ensure high-quality production.

Order Management

NetSuite outsourced manufacturing enables manufacturing units to deliver the perfect order every time with minimal effort and drive maximum benefits out of such trending opportunities.

Supply Chain Management

NetSuite manufacturing edition provides the same control and real-time visibility over a global supply chain and the related suppliers, contract manufacturers, and vendors locally. Irrelevant of location, this extensive manufacturing ERP solution helps ensure efficient planning, scheduling, coordination, and collaboration.

Why Choose inoday for NetSuite Manufacturing Edition?

Being an accredited #1 ORACLE NetSuite Channel Partner and recently acclaimed as India’s Top Solution Provider by NetSuite, we assist you in executing your business vision efficiently and driving unrivaled scalability. We are an accredited NetSuite Advanced Manufacturing Implementation Consultant and won many accolades for our willingness to respond, industry-specific expertise, and exemplary services to do away with operational bottlenecks.

Connect with our dedicated team at +91 120 432 9327

For detailed information, send an email to info@inoday.us Or Schedule A Demo!